Single-Screw Extrusion of Polymer Composites

Modeling pellet motion, melting, deformation, and fiber length attrition to capture the solid–melt transition and its effect on extrudate quality. Ph.D. thesis work.

Overview

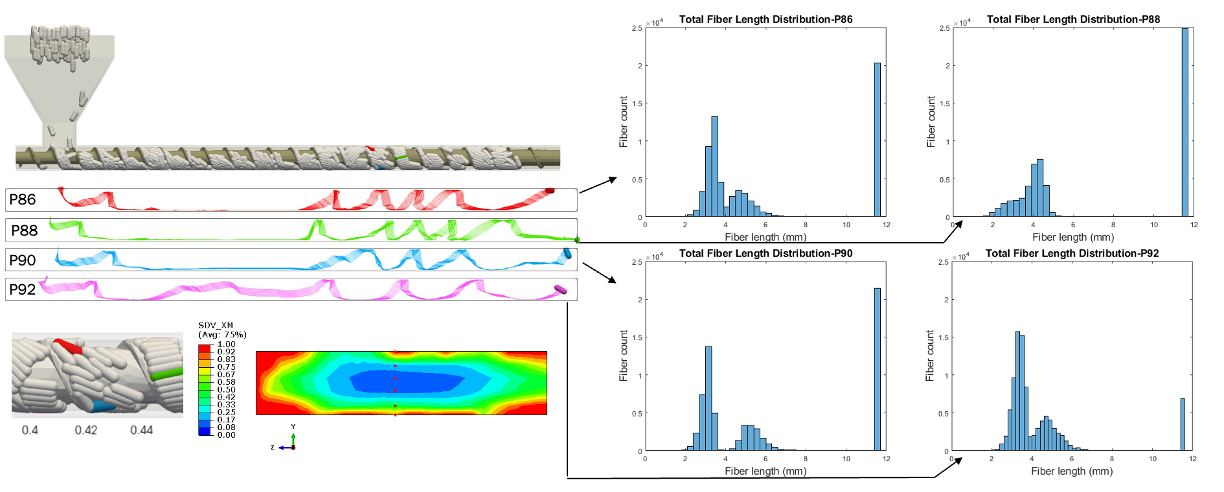

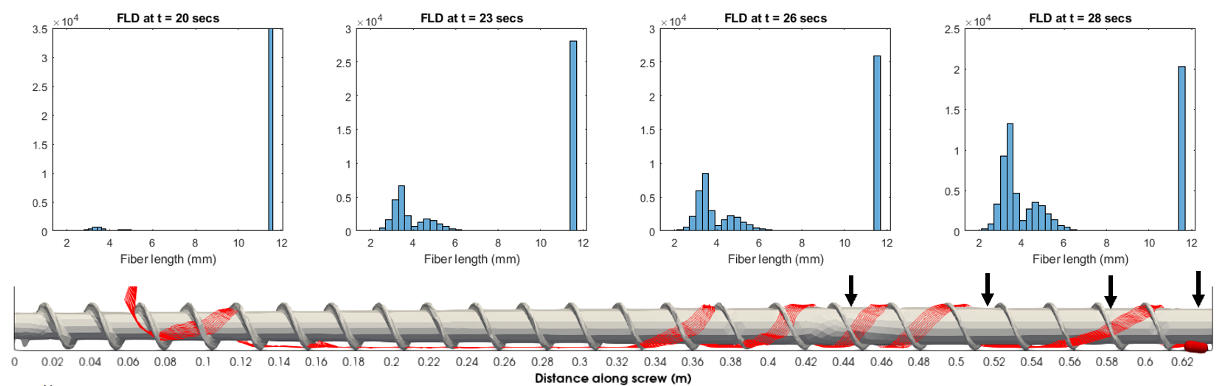

Developed a unified DEM–FEM–analytical modeling framework during my Ph.D. to predict pellet motion, melting, deformation, and fiber breakage for long-discontinuous fiber-reinforced polymer pellets. This work appears in my thesis and related publications (Kapre, 2024), (Kapre et al., 2025), (Kapre et al., 2024).

Approach

- DEM (LIGGGHTS) for pellet motion and kinematics

- FEM (ABAQUS) for heat transfer and melting of individual pellets

- Beam theory + Weibull model for pellet deformation and fiber breakage

- Coupled these into a melt progression + fiber-length evolution framework

Key Results

- Pellets recirculate primarily in the second half of the screw, aligning with rapid outside–in melting

- Fiber breakage initiates once the outer pellet layer melts

- Starve-feeding reduces residence time and fiber attrition; high RPM can cause incomplete melting

- Predicted bimodal fiber-length distributions match experiments

Impact

Provides a quantitative basis to tune screw geometry, feeding mode, and processing conditions to preserve fiber length and improve composite performance; extensible to other thermoplastic and extrusion-based AM feedstocks.

Tools

LIGGGHTS, ABAQUS, MATLAB, Python, HPC environment; Material: 40% CF-PPS

References

2025

2024

-

Fiber Length Attrition of Long-Discontinuous Fiber Reinforced Polymer Pellets in a Single Screw ExtruderPurdue University, 2024

Fiber Length Attrition of Long-Discontinuous Fiber Reinforced Polymer Pellets in a Single Screw ExtruderPurdue University, 2024 -

Modeling Flow of Long Discontinuous Fiber Reinforced Polymer Pellets in a Single Screw ExtruderIn Proceedings of the ASME Aerospace Structures, Structural Dynamics, and Materials Conference, 2024

Modeling Flow of Long Discontinuous Fiber Reinforced Polymer Pellets in a Single Screw ExtruderIn Proceedings of the ASME Aerospace Structures, Structural Dynamics, and Materials Conference, 2024