Process Optimization for Additive Manufacturing

Multi-physics modeling and process–structure–property optimization for large-format extrusion deposition. Collaboration with Lockheed Martin.

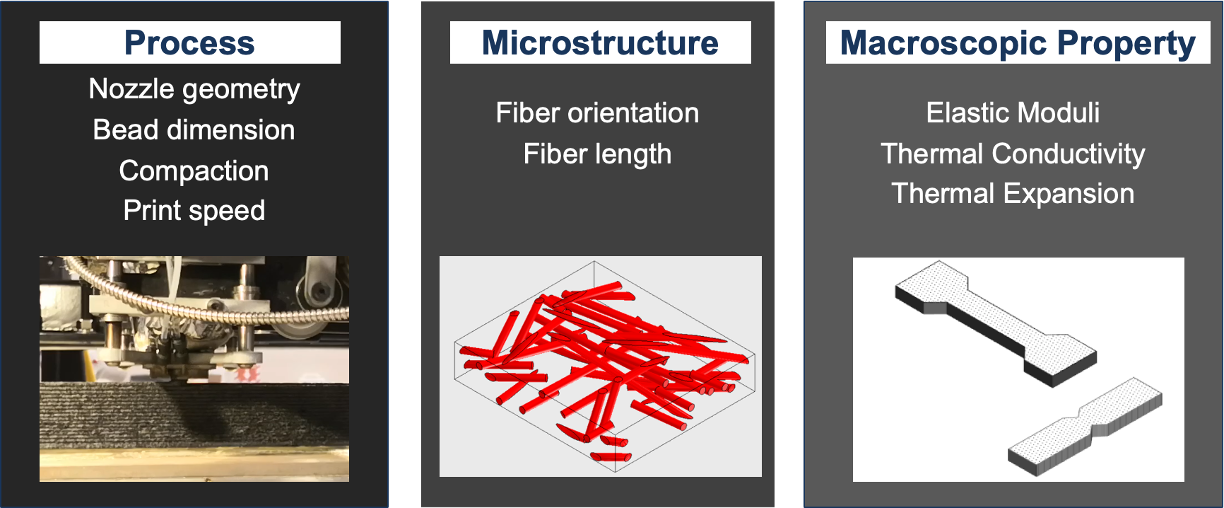

Overview

Investigated how printing parameters influence microstructure and macroscopic properties in large-format extrusion deposition of carbon-fiber-reinforced polymers. Designed the full experimental matrix, performed tensile testing, and processed data for journal and conference publications.

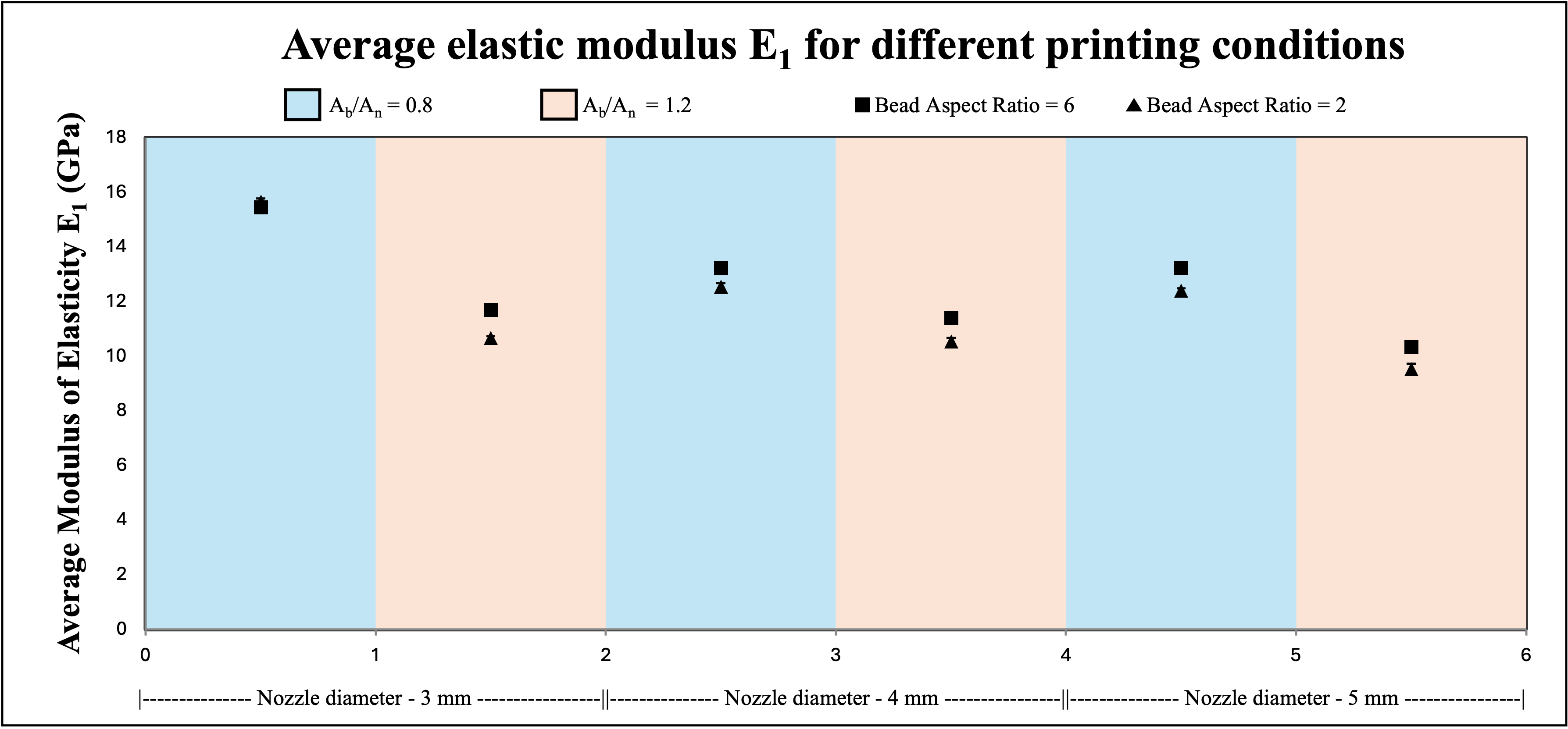

Elastic modulus trends for varying deposition parameters.

Approach

- Selected three dominant parameters (nozzle size, bead aspect ratio, bead/nozzle area ratio)

- Designed 12 printing conditions; fabricated and tested coupons (modulus & strength)

- Estimated fiber orientation (A₁₁) using micromechanics

- Ran ADDITIVE–3D virtual printing simulations using extreme material cards

Process–structure–property trends for carbon-fiber-reinforced PESU.

Key Results

- Elastic modulus range: 9.53–15.65 GPa; tensile strength: 92–145 MPa

- Fiber orientation A₁₁ spanned 0.60–0.77, capturing strong microstructure sensitivity

- Virtual parts showed 8.6% vs 9.5% deformation for low vs high orientation

- Demonstrated direct tuning of microstructure via printing parameters

Impact

Established a clear process–structure–property–performance link for fiber-reinforced AM, reducing trial-and-error and improving predictability for large or load-bearing components.

Tools

CAMRI printer, MTS tensile testing, MATLAB, ADDITIVE-3D (FEM-based); Material: 25% CF-PESU