Material Card Development

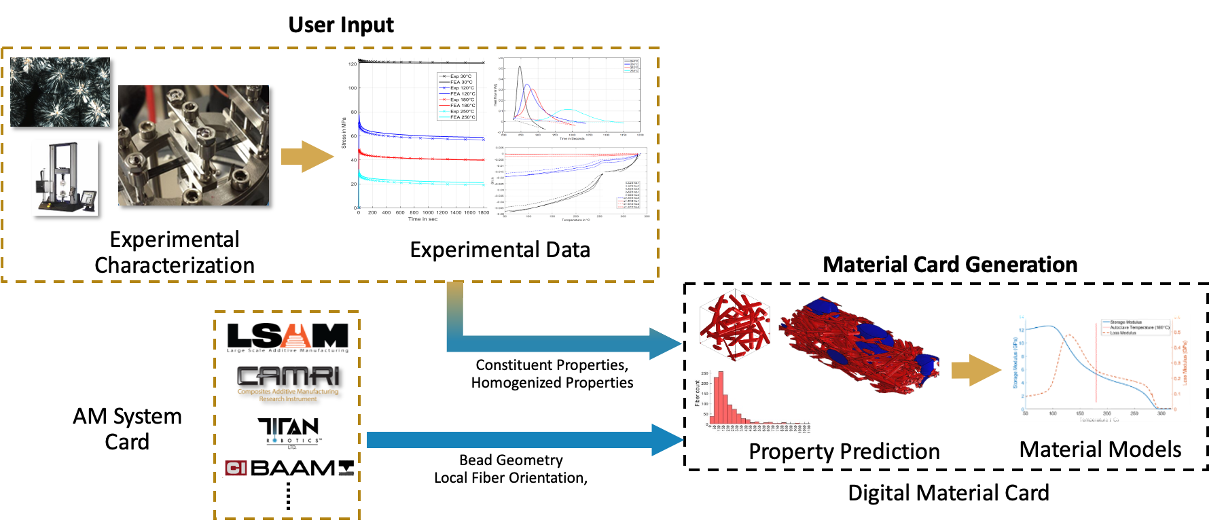

Experimental characterization and model calibration (microstructure, mechanical, thermal, viscoelastic) to generate validated material cards for 3D printing simulations.

Overview

Developed complete, orthotropic material cards for three carbon-fiber-reinforced thermoplastics (50% CF-PPS, 20% CF-PEI, 25% CF-PESU), enabling accurate extrusion-based AM simulations. Work conducted with Techmer and Lockheed Martin. (Barocio et al., 2022)

Experimental-to-simulation workflow for material card generation.

Approach

- Printed and tested coupons in printing, transverse, and stacking directions

- Quantified fiber-orientation tensors using optical microscopy and X-ray CT

- Performed DMA for viscoelastic behavior (Prony-series fitting)

- Used DSC to characterize crystallization and melting profiles

- Compiled complete orthotropic property sets for final material cards

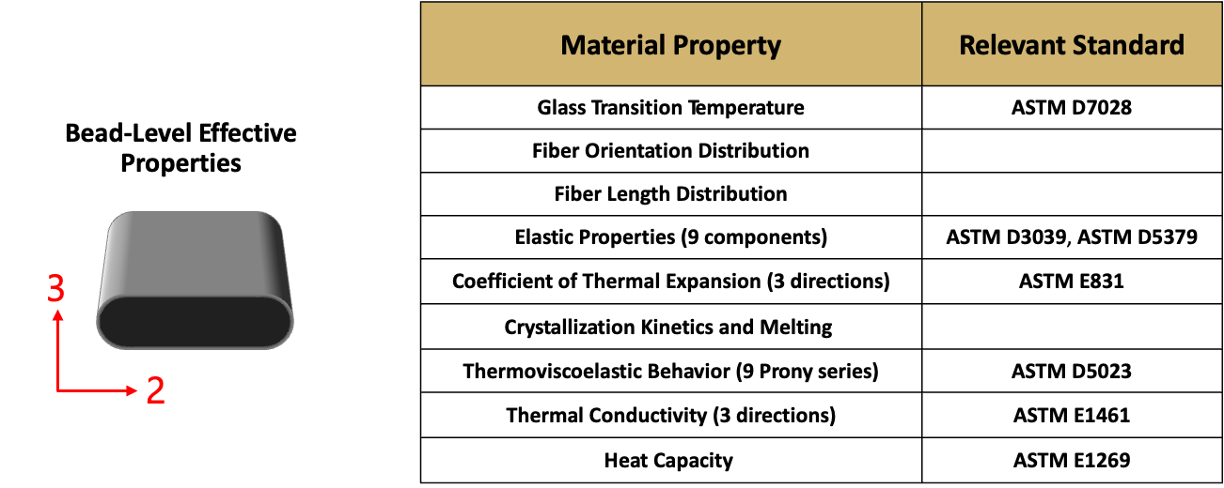

Required properties and corresponding ASTM standards.

Key Results

- Delivered fully validated material cards for all three material systems

- Implemented cards in ADDITIVE-3D; validated part deformation accuracy

- Produced comprehensive technical documentation for partners

Impact

Provides physics-based material inputs for AM simulations, improving deformation prediction and enabling reliable parametric studies for design and process optimization.

Tools

DSC, DMA, TGA, X-ray CT, optical microscopy, MTS tensile frames, MATLAB, Python, ADDITIVE-3D